1、 Product Features

The rectifier transformer used for intermediate frequency electric furnaces is a specialized transformer that provides rectifier power for intermediate frequency electric furnaces. According to the load characteristics of intermediate frequency electric furnaces, this transformer has strong overload capacity, low harmonic current, and good cooling effect. The voltage is 10KV-35KV, and the rectification methods are 6-pulse, 12 pulse, and 24 pulse.

2、 Reliable structure

Our company has made many improvements based on traditional structure and mature technology, such as adopting:

1. Spiral coil with longitudinal oil passage for better internal heat dissipation;

2. Improved the effective support of the coil end face, with stronger resistance to short-circuit current;

3. New lifting and positioning structures have been adopted to ensure greater reliability during long-distance transportation and operation;

4. Reasonably design the fuel tank, select the thickness of the steel plate and reinforcement measures based on the calculation results to ensure that the fuel tank can withstand vacuum and positive pressure requirements;

5. Adopt a reasonable box edge structure to ensure the strength and stiffness of the box edge; And add limit square steel on the edge of the fuel tank to ensure the elastic compression of the sealing gasket, so that the sealing gasket can effectively seal;

When designing the structure, full consideration should be given to facilitating leak testing and avoiding wire crossing.

3、 Good technical and economic performance

1. The iron core adopts high magnetic conductivity oriented silicon steel sheets with magnetic stretching reduction, which can effectively reduce the vibration of the transformer iron core;

2. Improve the iron core structure by adopting a five stage fully inclined joint;

3. Use cash processing equipment and technological measures to cut silicon steel sheets and stack iron cores.

4. Improve the connection between the body and the fuel tank by adding shock-absorbing pads between the body and the bottom of the tank;

5. Increase the thickness of the oil tank wall and the number of reinforcing irons appropriately to improve the stiffness of the entire transformer oil tank;

5. Purchase low-noise cooling fans and oil pumps.

6. The voltage electrode and internal metal components are rounded to prevent local electric field distortion and increase in field strength;

7. Purchase high-quality conductor and insulation materials, ensuring that the conductors and insulation materials are uniform and smooth, without any impurities or bubbles.

When assembling transformers, ensure sufficient vacuum degree, evacuation time, and static discharge time.

4、 Transformer product standards

GB/T9640-1999 Electric arc furnace transformer

GB/T5344.1-2004 General Principles for Submerged Arc Furnace Transformers

GB/T6303-2004 Technical Parameters and Requirements for Calcium Carbide Furnace Transformers

GB/T8506-2004 Technical Parameters and Requirements for Yellow Phosphorus Furnace Transformers

GB/T10429-2004 Ladle Refining Furnace Transformer

GB/T8447-2006 Transformers for electric slag furnaces

5、 Normal use conditions for transformers Special use conditions for transformers

Altitude not exceeding 1000m; Altitude exceeding 1000m;

Environmental temperature: Environmental temperature:

Maximum temperature+40 ℃ Maximum temperature+40 ℃

The average temperature of the hottest month is+30 ℃, and the lowest temperature is -25 ℃

The highest annual average temperature is+20 ℃

Outdoor minimum temperature -25 ℃

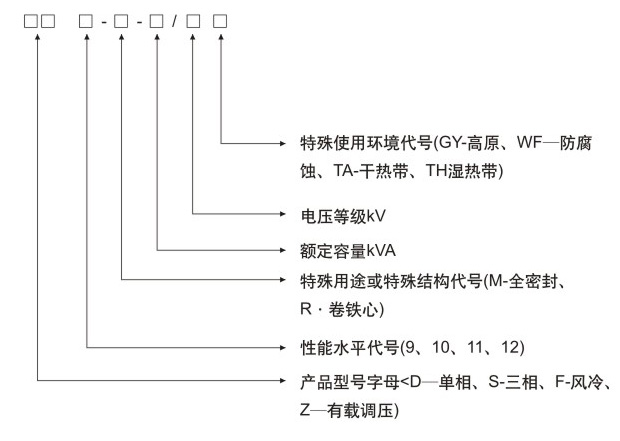

6、 Model meaning

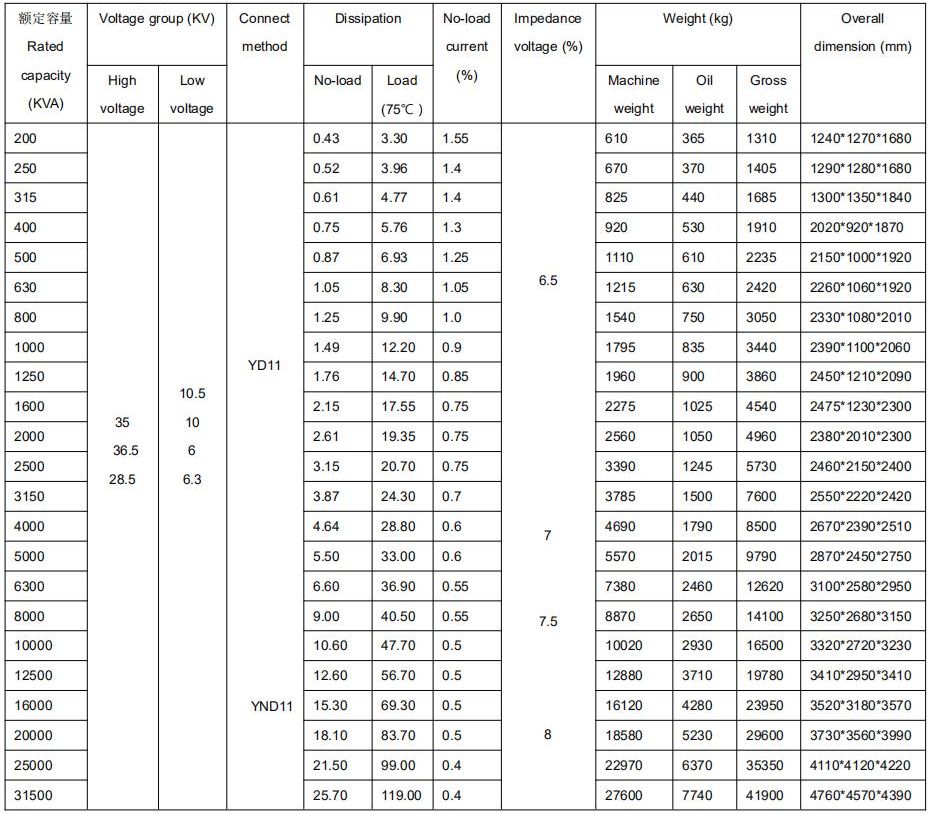

7、 Technical parameters

0379-68330098

0379-68330098

0379-68330098

0379-68330098