Product details

1、 Introduction to Three Dimensional Triangular Rolled Iron Core Power Transformer

Power transformers are widely used basic electrical products. For decades, laminated power transformers have been widely used in China and around the world, but their performance has not been fundamentally improved. The S13-M-RL and S11-M-RL series of three-dimensional wound iron core power transformers developed by Luoyang Longjian Transformer Co., Ltd. are another revolutionary product after laminated and wound iron core power transformers. It is a new type of energy-saving transformer with a more reasonable structure, better performance, and more significant energy saving.

With the second urban and rural power grid construction and renovation, as well as various power projects being launched, how to improve the technical content of power transformers, better implement national policies on energy conservation, consumption reduction, and environmental protection, and actively promote new products that are energy-saving, low consumption, and environmentally friendly has become an important issue facing us. The three-dimensional coiled iron core power transformer produced by Luoyang Longjian Transformer Co., Ltd. is a type of transformer that uses traditional materials, but has lower operating noise, lower losses, and better material conservation. It fully complies with international and domestic low-carbon economy and energy conservation and emission reduction policies. This product has been included in the first batch of energy-saving products selected for national energy-efficient power plants; National Resource Conservation and Environmental Protection Central Budget Investment Project; The State Economic and Trade Commission and the former State Grid Corporation of China have successively issued documents to promote this energy-saving product. The Shenyang Substation has also promoted the replacement of the three-dimensional coil iron core transformer as a stacked and flat coil iron core power transformer.

2、 A unique 'heart'

The iron core does not require cutting and has no punching, eliminating the transverse and longitudinal seams of traditional transformers and reducing magnetic resistance; The cross-section of the iron core column is polygonal, with the highest filling coefficient of the iron core. The triangular three-dimensional structure makes its three-phase magnetic circuit equal and shortest, achieving the ideal iron core structure of the transformer that people dream of. The triangular three-dimensional coiled iron core is a continuous steel strip from narrow to wide, and then from wide to narrow. Three single frame iron cores with a polygonal and semi half half spherical cross-section are first wound, and then assembled together in three dimensions to form a three-dimensional coiled iron core with three iron core columns with a cross-section similar to that of a country. The three-phase magnetic circuit is completely symmetrical and equal, shortening the iron roller and increasing the filling coefficient of the core column. Its structure is widely recognized as an ideal power transformer structure, which cannot be compared to a flat coil iron core. Experiments have shown that the three-dimensional coil iron core power transformer has better test data than a flat coil iron core power transformer. The three-dimensional coil iron core is a major breakthrough and leap in the structure of power transformer iron cores! Its birth is hailed as a revolution in the iron core of power transformers. Therefore, the three-dimensional wound iron core power transformer is widely recognized as an energy-saving, environmentally friendly, and ultra quiet green power transformer.

3、 Product Features

S13-M.RL new energy-saving three-dimensional coiled iron core transformer

Compared with the S7 transformer of the same capacity, the no-load loss has decreased by 55%, the load loss has decreased by 33%, the no-load current has decreased by more than 85%, and the noise has decreased by 8dB (A) -13dB (A)

Compared with the S9 transformer of the same capacity, the no-load loss has decreased by 50%, the no-load current has decreased by more than 80%, and the noise has decreased by 8dB (A) -11dB (A)

Compared with the national standard S11 transformer with the same capacity, the no-load loss has decreased by more than 25%, the no-load current has decreased by more than 70%, and the noise has decreased by 8dB (A) -11dB (A)

Compared to the standard S13 laminated structure with the same capacity, the no-load current of the transformer has decreased by more than 70%, and the noise has decreased by 5dB (A) -8dB (A)

Compatible with two voltages

The 111-M.RL -/10-20 and S13-M.RL -/10-20 solid triangle wound iron core transformers have two voltage compatible product series, 10kV and 20kV, which greatly facilitate users during the transition and update period from 10kV power grid to 20kV power grid.

Three phase magnetic circuit balance

The three-dimensional triangular coil iron core is composed of three identical single frames assembled together. The three core columns are arranged in an equilateral and angular shape, and the magnetic circuit lengths of the three core columns are exactly the same and the shortest. The losses of the three core columns are the same, so the three-phase magnetic circuit is balanced.

Stable quality and improved production efficiency

The similarity between three-dimensional triangular wound iron cores and flat wound iron cores lies in the fact that the iron cores are both wound on the production line without the need for transverse cutting equipment, eliminating the quality fluctuations caused by manual stacking, assembly, and disassembly of iron yokes in laminated iron cores; Compared to stacked core transformers, it can reduce 5-6 processes, resulting in high production efficiency, stable and reliable quality, and less susceptibility to human factors.

The structure of the three-dimensional triangular coil iron core transformer determines that its short-circuit resistance is better than that of the planar transformer, for the following reasons:

The frame and cushion blocks are evenly distributed around the body of the device. The three-phase forces are evenly and symmetrically distributed.

The compressed area of the coil increases by 15.7% compared to the compressed area of the coil arranged in a flat shape.

The clamp is a three-dimensional triangular frame structure, welded together as a whole. Due to the stability of the three-dimensional triangle, the overall strength is high, making the three phases uniformly stressed.

Anti theft

Stacked iron core transformers are prone to theft due to technical reasons. Remove the fasteners from the transformer body and knock off the silicon steel sheets. At this point, the three windings of the transformer are immediately separated from the silicon steel sheets, making it easy to steal and transport valuable materials such as silicon steel sheets and coils. Due to the fact that the iron core of a transformer with a coiled iron core is a whole, it cannot be knocked apart and the coil cannot be removed. It is also quite difficult to remove the entire iron core and coil, because the body weight of a 1OOKvA transformer is up to 400kg, and the body weight of a 200kVA transformer is 65Okg, making it difficult to separate valuable objects such as silicon steel sheets and copper wires. Therefore, coiled iron core transformers have good anti-theft properties.

Small footprint and beautiful appearance

The transformer oil tank adopts a nearly triangular structure, so its volume is smaller than that of a conventional rectangular oil tank, with a compact structure, beautiful appearance, and occupies less space.

Good product economy and high cost-effectiveness

Compared to transformers with the same energy level, the three-dimensional coil iron core transformer has lower loss values and lower operating costs. Therefore, it can reduce investment costs and save operating costs for users.

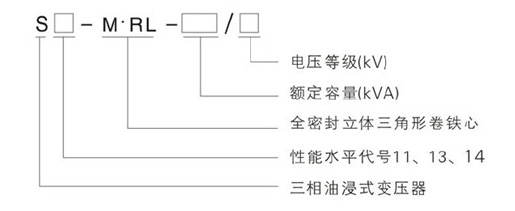

4、 Model meaning

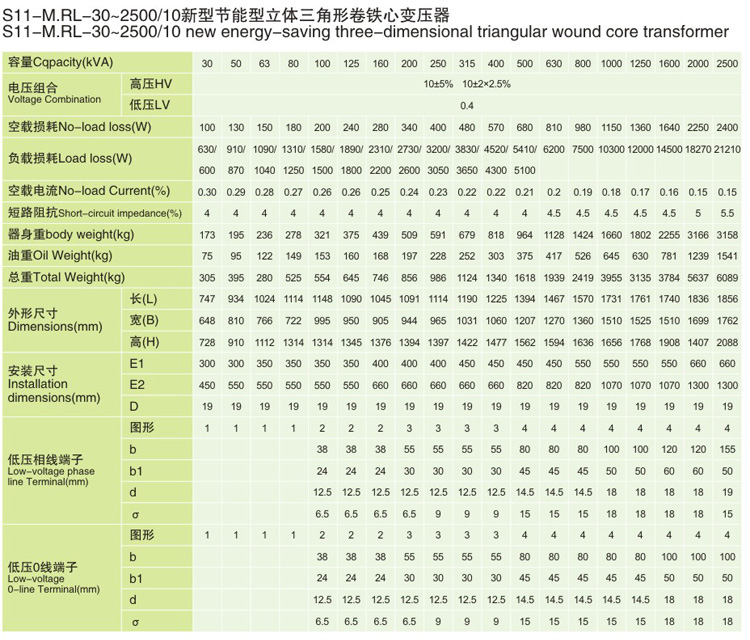

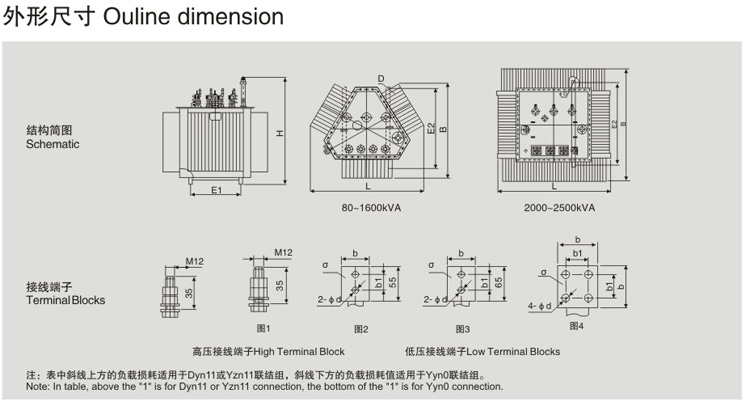

5、 Technical parameters

0379-68330098

0379-68330098