1、 Product Features

Resin insulated dry-type transformers are our company's introduction of advanced foreign technology and independent development of SC9, SCB9 series, as well as SC1O, SCB1O, SC11, SCB11 series with filler thin insulated dry-type transformers. Due to the coil being encapsulated by epoxy resin, it is flame retardant, fire-resistant, explosion-proof, maintenance free, pollution-free, small in size, and can be directly installed in load centers. At the same time, the scientific and reasonable design and pouring process result in smaller partial discharge, low noise, and strong heat dissipation capacity of the product. It can operate for a long time under 140% rated load under forced air cooling conditions, and is equipped with an intelligent temperature controller with fault alarm, overtemperature alarm, overtemperature trip, and black gate functions. It is connected to the computer through RS485 serial interface for centralized monitoring and control.

Due to the above characteristics of our company's dry-type transformers, they are widely used in power transmission and transformation systems, such as hotels, restaurants, airports, high-rise buildings, commercial centers, residential areas and other important places, as well as in harsh environments such as subways, smelting power plants, ships, and offshore drilling platforms.

Iron core

The iron core is made of imported high-quality cold-rolled silicon steel sheets, and the iron core is made of imported high-quality cold-rolled silicon steel sheets with a fully angled terminal structure. The core column is tied with F-grade non warp adhesive tape, and the surface of the iron core is encapsulated with epoxy resin to reduce no-load loss, no-load current, and iron core noise. The clamps and fasteners are specially surface treated to further improve the appearance quality of the product.

High voltage winding

The high-voltage winding is vacuum cast with filler ring resin, greatly reducing the local discharge and improving the electrical strength of the coil. The inner and outer walls of the winding are filled with fiberglass mesh plates, enhancing the mechanical strength of the coil and improving the product's ability to resist sudden short circuits. The coil never cracks.

Low voltage winding

The low-voltage winding adopts a foil structure, which solves the problem of axial helix angle when using wire winding, making the turns more balanced. At the same time, the coil adopts an axial cooling air duct, enhancing the heat dissipation ability. TD epoxy resin prepreg is used between the winding layers, and the whole is cured and formed.

Manufacturing process

The coil is wound on a high-precision winding machine, and the low-voltage winding adopts a foil winding structure. When the capacity of the transformer is large, there is a ventilation duct for winding, and then vacuum drying is carried out. The entire casting and curing process is completely operated according to the process requirements, and all processes need to be strictly monitored and adjusted according to the situation. The precision manufacturing process of casting is adjusted as needed to ensure that the coil has no bubbles or voids, and the resulting transformer achieves high-quality operation.

Temperature control system and air cooling system

The cross flow top blowing cooling fan is adopted, which has the characteristics of low noise, high air pressure, and beautiful appearance, enhancing the overload capacity of the transformer. The temperature control adopts an intelligent temperature controller, which improves the safety and reliability of transformer operation.

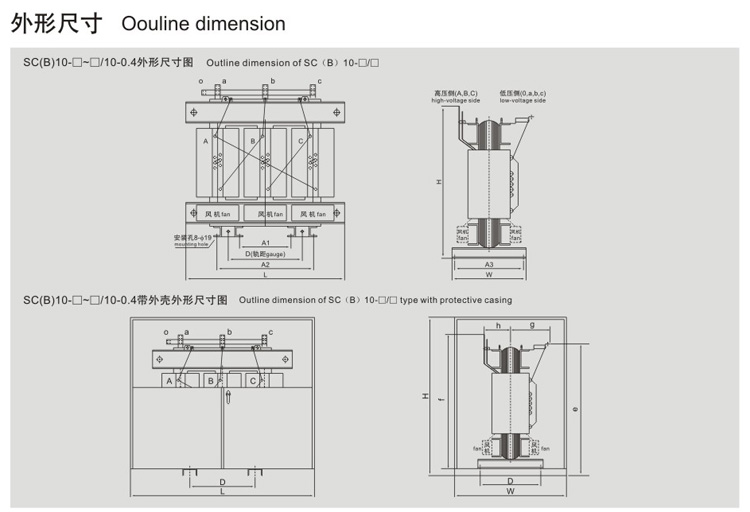

Protect the casing and output busbar

The protective shell provides further safety protection for the transformer, with protection levels such as IPZO, IP23, etc. The shell materials include cold-rolled steel plates, stainless steel plates, etc. for users to choose from for low-voltage outgoing lines using standard busbar strips, both side and top outgoing lines are available, and special outgoing methods can also be designed for users.

Transformer outgoing line method

Conventional outgoing lines, standard enclosed busbars, and standard side outgoing lines can be manufactured according to different interface forms, and special outgoing methods can also be designed according to user requirements.

Product standards

GB/T10228-2008 GB109411-2007 JB/T10088-2004 GB4208-1993

Rated high voltage: 10 (11,10.5,6.6,6.3,6) KV

Rated low voltage: 0.4kV

Connection group: Dynll or Yyn0

High voltage tap range: ± 5% or ± 2 × 2.5%

Insulation level LI75AC35/LIOAC5

Frequency: 50Hz

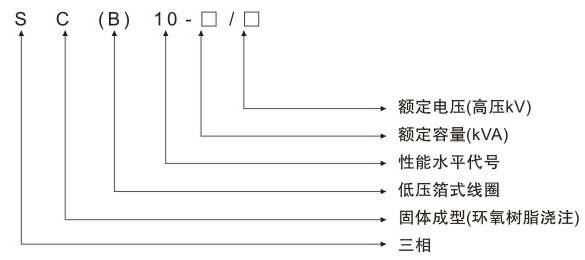

2、 Model meaning

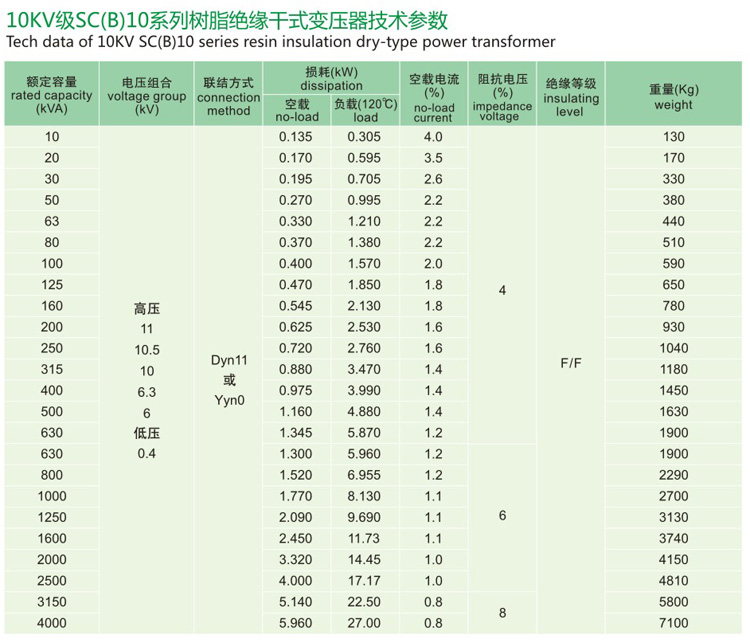

3、 Technical parameters

0379-68330098

0379-68330098

0379-68330098

0379-68330098